CDMOs like Particle Sciences contain the machines and staff in position to both create and scale-up sterile lyophilization processes.

For companies for example Spine BioPharma, Viscogliosi states Emergent provides a 1-end providing for drug production requires—from growth and optimization to commercialization.

Enhancements in warmth transfer: One of several most vital leaps in present day freeze-drying is the improvement in heat transfer systems. By optimizing the strategy and amount of warmth shipping and delivery on the solution, It truly is now feasible to keep up products excellent while substantially lessening drying moments.

Beyond the biological pros lyophilization may facilitate sustainability. In the present remarkably collaborative scientific Local community there is a escalating want to move Organic samples. Liquid nitrogen or dry ice will not be required for your storage of freeze-dried samples, which appreciably lessens shipping and storage expenses (Lewis et al.

Liquid nitrogen: safety and dangers Virtually every spot in which liquid nitrogen is employed has a number of warning signals or stickers. “Danger,” “do

take a look at for all parametrical comparisons, or in the case of nonparametric information by Wilcoxon check on ranks. To test homogenization effectiveness, variances within Each and every group were being in contrast by Levene’s take a look at carried out in Microsoft Office Excel (Microsoft, Redmond, WA, United states) the place one component ANOVA was placed on absolute variances of values to suggest. Significance was established a priori at P

These partially stoppered vials are transported on the lyophilizer and loaded in beneath aseptic circumstances

Whilst drinking water vapor flows from within the product to the outside, warmth transfer have to go in the alternative route. Owing to the lower thermal conductivity of your dried product or service layers, the temperature gradient necessary for warmth transfer steadily increases. In order to avoid products injury, the utmost probable temperature for the dried product need to not be exceeded.

The process of lyophilization stands being a cornerstone in pharmaceutical manufacturing, preserving the integrity of biologics and biological products for over 80 yrs. By means of meticulous freezing, get more info drying, and vacuuming stages, lyophilization yields steady pharmaceutical powders with prolonged shelf life, pivotal for prevalent distribution and Protected use.

Freeze-drying demands specialised and often high priced equipment that actually works under a selected temperature and stress.

Furthermore, due to the fact most reactions that can degrade products require a selected tension level to carry on, protecting a decreased strain can further more boost products stability and safety for the duration of freeze-drying.

Cryoprotectants assistance keep the structural integrity of your merchandise by safeguarding drug substance molecules against drying stresses and, in the situation of biologics, support keep conformation and prevent agglomeration. Bulking brokers can also be added on the formulation to make certain a steady and chic cake write-up lyophilization.

When Key drying is effectively finish, the process has typically eliminated among 90-ninety five% on the solvent and manufactured a bodily secure lyophilized matrix. There is a single dilemma, on the other hand; there is often remaining solvent that's bound concerning crystals that can not be fully faraway from the Electricity input of sublimation alone. The final phase – secondary drying, requires further more removal from the residual humidity from the lyophilized merchandise by escalating the temperature and eradicating bound solvent by way of desorption.

Bound drinking water remains in the vial as it is actually mounted to The inner composition by Exclusive bonds. Interstitial fluids now lie involving the ice crystals and type a ongoing Internet that contains all of the compounds inside more info the first procedure.

Jaleel White Then & Now!

Jaleel White Then & Now! Barry Watson Then & Now!

Barry Watson Then & Now! Heather Locklear Then & Now!

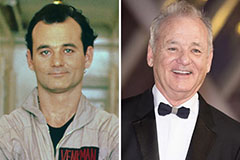

Heather Locklear Then & Now! Bill Murray Then & Now!

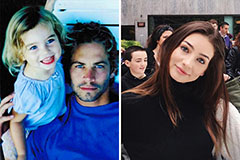

Bill Murray Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!